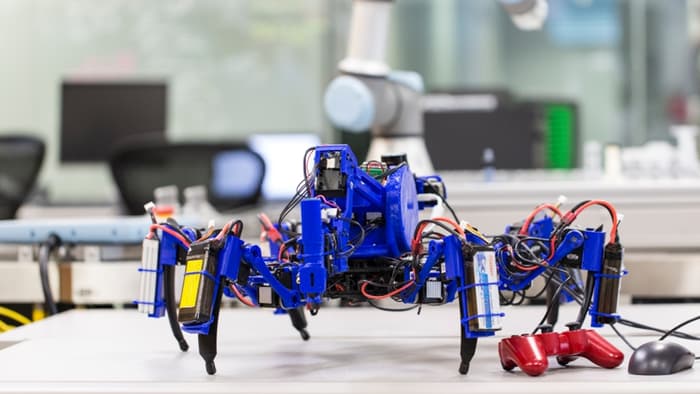

Siemens previews additive manufacturing on the move with 3D-printing spider bots

If the thought of your workplace being invaded by hundreds of laptop-sized, creepy-crawly robots fills you with dread, Siemens' vision of the future industrial worker probably isn't going to be your cup of tea. A research team working in the Siemens Robotic Labs at Princeton, New Jersey, has developed what are essentially autonomous 3D printers with legs, which could work together to manufacture complex structures such hulls of ships or the fuselage of an airplane.

"We are looking at using multiple autonomous robots for collaborative additive manufacturing of structures, such as car bodies, the hulls of ships and airplane fuselages," said head of Siemens' Product Design, Modeling and Simulation Research Group, Livio Dalloro.

The spider-like prototype robots have been named SiSpis, which simply stands for Siemens Spiders, and the team used off-the-shelf motors and cables in the construction of the autonomous manufacturing machines, but everything else was created and developed in-house, including 3D-printed components used in the build.

They have onboard cameras and a laser scanner to help them understand their surroundings and know exactly where they are in any given space. Algorithms developed by the team cater for two or more robots to plan and collaborate on the 3D printing or surface processing of an object or area. Since a robot's 3D-printing arm is a known variable, each spider bot can determine the work area it's able to cover. The total work area is divided into vertical boxes and the bots collaborate to ensure that all boxes in a grid are covered.

Each spider can work for around 2 hours before its battery needs some charging attention, with a robot scuttling back to its charging station before completely running out of juice. It will first transmit its last active location to another fully-charged bot, though, so that work can continue without interruption. And if a spider encounters an obstacle during its travels, it will automatically find a way around it.

For the moment, the prototypes don't print in materials common to other 3D printing machines, such as plastic, but extrude a mix of cornstarch and sugarcane, but they could in the future. The aim of the project, which has been running since early 2014, was to create a platform for manufacturing machines that can autonomously weigh up a task, divide the work among available robots and then collaborate on performing the job at hand.

This appears to have been achieved, but Siemens isn't currently offering any clues as to when, or even if, we might see 3D printing spiders in the workplace.

Source: Siemens Research